KAPTOL EPOXY FLOORING

As a Newcastle resident you will understand how valuable your property is.

Keeping it painted is a vital part of its maintenance. Newcastle is known as a great place to live. This means there is a high demand for houses and house maintenance services. From painting to flooring, keeping your home or commercial property looking great is a part of every day life.

That's where Kaptol Epoxy Flooring comes in. We are a full service epoxy painting company which can take care of all your floor painting needs. Don't trust just anyone to look after your home or commercial flooring, trust Kaptol Epoxy Flooring. We have been serving the people of Newcastle for years and we know what it takes to keep your property maintained and looking great.

Professional Epoxy Flooring Services

Home, Garage, Office, Commercial, Government.

Kaptol Epoxy Floors is a local, Australian owned company.

We don't do ordinary!

We strive to exceed your expectations in every way by providing premium services using only the highest quality epoxy flooring products.

Our qualified and experienced team of tradesmen, estimators, and managers are committed to ensuring your satisfaction from the moment we receive your request until we finish your project.

We work hard to maintain our market-leading reputation of providing high-quality epoxy floor coatings.

We constantly invest in superior and technologically advanced equipment.

We ensure every team member receives the best training, which ensures that we can provide you with the most environmentally friendly, and cost-effective epoxy flooring options available.

GET A FREE QUOTE

We will get back to you as soon as possible.

Please try again later.

Have you just built or renovated your home or commercial space?

Have you considered a fresh new look and feel for your floors?

How about a floor that doesn't require constant maintenance or repairing?

Epoxy Flooring might be the answer.

The latest advancements in epoxy flooring make it a durable, long-lasting and logical solution for your home, garage or commercial property.

You can add a sense of elegance and sophistication to your property by choosing from a wide range of colours and finishes.

This extraordinary, seamless finish will leave a lasting impression on your friends and customers.

Forget about tiresome floor maintenance, a few minutes with a mop and you'll have it sparkling again!

Epoxy flooring is perfect for restaurants, cafes and food related businesses. It presents a hygienic surface which will resist stains and can be easily cleaned without the use of harsh cleaners or chemicals, making it safer for your employees and patrons.

When you are ready to take your flooring to the next level, get in touch with Kaptol Epoxy Flooring, you'll never look back!

What is Epoxy?

Epoxy is a type of thermosetting polymer that is formed by the reaction between an epoxy resin and a hardener.

It is commonly used in a wide range of applications due to its excellent bonding properties, durability, and resistance to chemicals, heat, and water.

Here are some of the properties and applications of epoxy and its importance in various industries.

Epoxy resins are made from a combination of bisphenol A and epichlorohydrin. When the two chemicals are combined, they create a liquid or a solid polymer that can be used for a variety of applications. The epoxy resin is then mixed with a hardener, which triggers a chemical reaction that causes the mixture to harden and form a strong, durable bond.

One of the key properties of epoxy is its high strength and durability.

This makes it an ideal material for applications that require a strong and long-lasting bond, such as in construction, automotive, and aerospace industries.

Epoxy can also resist corrosion, making it an excellent choice for use in marine applications.

Another important property of epoxy is its resistance to chemicals and heat. Epoxy can withstand exposure to a wide range of chemicals, including acids, solvents, and fuels, making it an ideal choice for use in chemical processing and industrial applications.

It is also able to withstand high temperatures, making it suitable for use in high-temperature environments, such as aircraft engines and industrial ovens.

Epoxy is also a popular material for use in art and crafts, particularly in the creation of jewellery, sculptures, and other decorative objects. Its ability to be molded into different shapes and its ability to be coloured and tinted make it a versatile material for creative projects.

In addition to its mechanical and physical properties, epoxy is also easy to work with.

It can be mixed, poured, and molded into various shapes and sizes, and it can be used with a variety of substrates, including metals, plastics, and ceramics. It can also be applied to surfaces, including floors, as a coating, providing an additional layer of protection and durability.

Epoxy is a versatile and important material that has a wide range of applications in various industries. Its strength, durability, resistance to chemicals and heat, and ease of use make it a popular choice for use in construction, automotive, aerospace, and industrial applications. Its versatility also makes it a popular choice for art and crafts projects. As technology advances, the use of epoxy is likely to continue to grow, and it will remain an important material for a wide range of applications.

Is Epoxy Different From Paint?

Epoxy and paint are two popular coating materials used in various applications, ranging from automotive and industrial to residential and commercial.

While both epoxy and paint provide a protective layer on surfaces, they differ in several aspects, including their composition, application, and performance.

Let's look at the differences between epoxy and paint.

Composition:

Epoxy and paint are made up of different components.

Epoxy is a two-part system that consists of a resin and a hardener. When the two are combined, they create a chemical reaction that leads to a hard, durable, and high-strength coating.

On the other hand, paint is typically made up of pigments, binders, solvents, and additives, which are mixed together to create a liquid that is applied to a surface.

Application:

The application process for epoxy and paint is different.

Epoxy is applied using a two-step process, where the resin and hardener are mixed together in a specific ratio, and then applied to a surface. The mixture has a limited working time, and once it starts to harden, it cannot be applied.

In contrast, paint is applied using a one-step process, where the paint is directly applied to the surface using a brush, roller, or spray gun.

Performance:

Epoxy and paint differ in their performance characteristics.

Epoxy is known for its high strength, durability, and chemical resistance, making it suitable for use in industrial and commercial applications. It can withstand heavy traffic, harsh chemicals, and extreme temperatures. Epoxy is also resistant to abrasion, impact, and moisture, which makes it ideal for use on floors, walls, and other surfaces.

Paint, on the other hand, is less durable than epoxy and is prone to chipping, fading, and peeling. It is typically used for aesthetic purposes, such as adding colour and texture to surfaces.

Cost:

The cost of epoxy and paint also differs.

Epoxy is typically more expensive than paint, as it is a high-performance coating that requires specialized application techniques and materials. Additionally, the cost of labour for applying epoxy is typically higher than that of paint, due to the additional preparation and application steps involved.

So, epoxy and paint are two different coating materials that differ in their composition, application, performance, and cost.

Epoxy is a high-performance coating that is known for its strength, durability, and chemical resistance, while paint is primarily used for aesthetic purposes. When deciding which material to use, it is important to consider the specific application and performance requirements, as well as the budget and timeline for the project.

What is Epoxy Flooring?

Epoxy flooring is a type of surface that consists of multiple layers of epoxy resin applied to a floor base.

This resin, a combination of a polymer hardener and a resin, creates a chemical reaction that forms a rigid plastic material.

The result is a strong, seamless, and highly durable surface that adheres firmly to concrete, wood, and other substrates.

Types of Epoxy Flooring

- Self-Leveling Epoxy Floors: These are smooth and aesthetically pleasing, often used in commercial spaces like warehouses, showrooms, kitchens, and offices. They are also popular in residential areas, particularly for garages and basements.

- Epoxy Mortar Floors: This is the strongest type of epoxy flooring, used in heavy-duty environments. It’s ideal for industrial settings that endure a lot of weight, impact, and high traffic, such as warehouses and manufacturing plants.

- Quartz-Filled Epoxy Floors: These floors combine high-performance epoxy polymer resin with stained quartz grains, creating a durable and decorative floor. They’re often used in restrooms, change rooms, schools, cafeterias, and lobbies.

- Epoxy Flake Floors: These have coloured flakes added to them, creating a vibrant, multi-hued look. This style is popular in retail spaces, sports venues, and car showrooms, offering a decorative touch while maintaining the durability of epoxy.

- Anti-Static Epoxy Floors: Also known as Electro-static charge (ESD) resistant floors, these are designed to mitigate any static hazards. They are ideal for areas where electronic components are handled or stored, such as hospitals, laboratories, and manufacturing facilities.

What are the Pro's and Con's of Epoxy Flooring?

Epoxy flooring is a type of floor coating applied over concrete surfaces to create a smooth, durable, and visually appealing surface.

It is composed of a mixture of resin and hardener that, when combined, creates a tough plastic material. Epoxy floors are becoming increasingly popular in both residential and commercial spaces due to their numerous benefits, but they also come with a few drawbacks to consider.

Here are some pros and cons of using epoxy flooring:

Pros of Epoxy Flooring

- Durability: Epoxy flooring is renowned for its exceptional durability. It is highly resistant to damage from impact, abrasion, and chemicals, making it ideal for environments that experience heavy use. Whether it’s a garage, warehouse, or industrial plant, epoxy flooring can withstand the stress of heavy foot traffic, forklifts, and other machinery without showing signs of wear and tear.

- This makes it a popular choice for spaces where longevity and resilience are crucial.

- Aesthetics: Available in a variety of colours, patterns, and finishes, epoxy flooring can be customized to match the aesthetic of any space. From solid colours to metallic finishes and decorative flake patterns, epoxy offers a polished and professional look that can enhance the overall appearance of both residential and commercial interiors. This flexibility in design makes it a versatile option for both practical and decorative purposes.

- Easy Maintenance: Epoxy floors are non-porous, which means they do not absorb liquids, dirt, or grime. This feature makes them incredibly easy to clean and maintain. Spills can be quickly wiped up without leaving stains, and regular sweeping or mopping keeps the floor looking new. This low-maintenance quality is particularly beneficial for businesses and homeowners looking to reduce cleaning time and costs.

- Slip-Resistant: Safety is a major concern in commercial and industrial environments. Epoxy flooring can be customised with slip-resistant additives, providing additional grip to prevent accidents. This makes it an ideal choice for areas prone to spills, such as kitchens, bathrooms, garages, and warehouses. The added traction reduces the risk of slips and falls, ensuring a safer environment for employees, customers, or residents.

- Cost-Effective: Compared to other flooring options like tile, hardwood, or stone, epoxy flooring is relatively inexpensive. Its lower initial cost, combined with its longevity and minimal maintenance requirements, makes it a cost-effective solution for many applications. For those looking to achieve a high-quality, durable floor without spending a fortune, epoxy flooring is a strong contender.

- Chemical Resistance: Epoxy flooring is highly resistant to a wide range of chemicals, including oils, solvents, and cleaners. This makes it an excellent choice for industrial settings, garages, and laboratories where chemical spills are common. The resistance to chemical damage helps maintain the floor's appearance and functionality over time, further extending its lifespan.

- Seamless Surface: The seamless nature of epoxy flooring eliminates cracks and crevices where dirt, bacteria, and other contaminants can accumulate. This is particularly important in healthcare settings, food processing plants, and other environments where hygiene is critical. A seamless surface is easier to clean thoroughly, helping to maintain a sanitary environment.

Cons of Epoxy Flooring

While epoxy flooring has many advantages, it’s also important to consider some of its potential drawbacks:

- Installation Time and Process: Installing epoxy flooring is not a quick process. The concrete surface must be properly prepared, cleaned, and primed before applying the epoxy. The curing time can take several days, during which the area must remain unused. Any mistakes during installation can result in imperfections that are difficult to fix. Professional installation is often recommended to ensure the best results, which can add to the cost.

- Potential Slipperiness When Wet: Although epoxy can be made slip-resistant, it can still become slippery when wet, especially if it has a high-gloss finish. This can pose a risk in areas where water or other liquids are frequently present. To mitigate this risk, additives like textured granules or anti-slip coatings can be applied, but they may affect the floor's appearance.

- Limited Flexibility: Epoxy flooring is a rigid material, which means it does not tolerate substrate movement well. If the concrete base underneath the epoxy shifts or cracks, the epoxy flooring may crack as well. This can be a concern in areas prone to ground movement or where the underlying concrete is not in good condition.

- UV Sensitivity: Epoxy flooring can be sensitive to UV light, causing it to yellow or fade over time if exposed to direct sunlight. This can be an issue for areas with large windows or outdoor spaces. To counteract this, UV-resistant topcoats can be applied, but they may add to the overall cost of the installation.

- Odour During Installation: During the installation and curing process, epoxy flooring can emit strong fumes due to the chemicals used. Proper ventilation is required to minimise exposure to these fumes, which can be harmful if inhaled in large quantities. The odour typically dissipates once the floor is fully cured, but sensitive individuals may find it bothersome during installation.

- Cold Sensitivity: In colder climates, epoxy floors can become quite cold to the touch. This is especially noticeable in residential settings where people may walk barefoot. While this may not be a significant concern in industrial or commercial settings, it’s something to consider for homeowners who prioritise comfort.

- Repair Challenges: While epoxy is durable, it is not immune to damage. Cracks or chips can occur, especially in high-impact areas. Repairing epoxy floors can be challenging; the damaged area may need to be completely removed and reapplied, and colour matching can be difficult.

How Long Will and Epoxy Floor Last?

The lifespan of epoxy flooring can vary significantly based on several factors, including the quality of materials used, the preparation and application process, the environment in which the floor is installed, and the amount of traffic and wear it endures.

Generally, a well-installed epoxy floor can last anywhere from 5 to 20 years or even longer, making it a popular choice for both residential and commercial spaces.

Factors Affecting the Lifespan of Epoxy Flooring

- Quality of Materials: The quality of the epoxy resin and hardener used in the flooring plays a crucial role in its durability. Higher-quality epoxy products tend to have better adhesion, resistance to chemicals and impact, and overall durability. Investing in premium-grade materials can significantly extend the life of the floor, as they are less likely to degrade or fail over time.

- Surface Preparation: Proper surface preparation is essential for ensuring the longevity of an epoxy floor. The underlying concrete surface must be thoroughly cleaned, repaired, and primed to ensure the epoxy adheres properly. Any moisture, oil, dirt, or debris left on the surface can cause the epoxy to bubble, peel, or fail prematurely. A well-prepared surface provides a strong foundation for the epoxy, reducing the risk of issues down the line.

- Installation Process: The installation process also plays a critical role in determining how long an epoxy floor will last. The epoxy must be mixed and applied correctly to ensure it cures properly. Applying the epoxy in the right environmental conditions—such as the correct temperature and humidity levels—is crucial to avoid issues like bubbling, peeling, or cracking. A professional installation will help ensure these factors are managed effectively, leading to a longer-lasting floor.

- Level of Traffic and Use: The amount and type of traffic the floor endures are significant factors in its lifespan. In residential settings, like garages or basements, where foot traffic and vehicle movement are relatively light, epoxy flooring can last 15 to 20 years or more. However, in commercial or industrial settings with heavy machinery, forklifts, and constant foot traffic, the floor may require more frequent maintenance and might last closer to 5 to 10 years.

- Environmental Factors: Environmental conditions, such as exposure to extreme temperatures, moisture, and UV light, can affect the lifespan of epoxy flooring. For example:

- Extreme Temperatures: Epoxy floors can become brittle or crack in environments with frequent temperature fluctuations, especially if the concrete underneath expands and contracts.

- Moisture: Excessive moisture or water vapor coming through the concrete can cause the epoxy to delaminate or peel away from the surface.

- UV Light Exposure: Prolonged exposure to direct sunlight can cause epoxy flooring to yellow, fade, or degrade over time. UV-resistant topcoats can be applied to mitigate this, but regular maintenance may still be required.

- Maintenance Practices: Regular maintenance plays a crucial role in prolonging the life of an epoxy floor. Keeping the floor clean, addressing spills or stains promptly, and avoiding the use of harsh chemicals can help maintain its appearance and integrity. Additionally, applying a protective topcoat every few years can further extend the floor's lifespan by adding an extra layer of protection against wear and tear.

General Lifespan Expectations for Epoxy Flooring

- Residential Settings: In areas such as garages, basements, and home workshops, where foot traffic and vehicle movement are moderate, epoxy floors can easily last 10 to 20 years. Proper installation and regular maintenance can even extend this lifespan beyond 20 years.

- Commercial Settings: In commercial spaces like retail stores, showrooms, and office buildings, epoxy flooring may experience moderate foot traffic and occasional use of light equipment. With proper care, these floors can typically last between 5 and 15 years.

- Industrial Settings: In environments with heavy machinery, constant forklift traffic, and exposure to chemicals or abrasive materials—like factories, warehouses, and automotive service centers—the lifespan of epoxy flooring may range from 5 to 10 years. Frequent maintenance, such as reapplying protective coatings, can help maximise the lifespan under these demanding conditions.

Maximising the Lifespan of Epoxy Flooring

To ensure that your epoxy floor lasts as long as possible, consider the following best practices:

- Hire Professional Installers: Proper installation is critical to the longevity of epoxy flooring. Hiring experienced professionals ensures that the surface is correctly prepared, the materials are mixed and applied properly, and environmental conditions are monitored during curing.

- Regular Cleaning and Maintenance: Sweep and mop the floor regularly to remove dirt and debris that could cause scratches or abrasions. Use mild cleaning agents and avoid harsh chemicals that can damage the epoxy finish.

- Apply Protective Coatings: Over time, the top layer of an epoxy floor may show signs of wear. Applying a new topcoat every few years can help maintain the floor’s appearance and protect it from further damage.

- Minimise UV Exposure: In areas with large windows or outdoor exposure, consider adding UV-resistant coatings or treatments to protect against discoloration and degradation.

- Address Repairs Promptly: If cracks, chips, or other damage appear, address them promptly to prevent the damage from spreading. Quick repairs can extend the overall life of the floor and prevent costly replacements.

The lifespan of an epoxy floor varies depending on several factors, such as material quality, surface preparation, installation, traffic, and environmental conditions. With proper installation, regular maintenance, and prompt repairs, epoxy flooring can provide a durable, long-lasting solution for a variety of settings, from residential garages to industrial warehouses. While the lifespan can range from 5 to 20 years or more, understanding these factors and taking the right steps can help maximize the value and durability of your epoxy flooring investment.

What is Epoxy Flake Flooring?

Epoxy flake flooring is a type of flooring system that uses a combination of epoxy resin and coloured vinyl flakes to create a durable, attractive surface.

The epoxy resin is a thermosetting polymer that is mixed with a hardener to form a rigid, plastic-like material. The vinyl flakes are available in a variety of colours and sizes, and are broadcasted onto the wet epoxy resin layer to create a decorative finish.

The result is a seamless, slip-resistant, and easy-to-clean surface that is ideal for commercial and residential applications.

Epoxy flake flooring is commonly used in garages, workshops, retail stores, and other high-traffic areas. The flooring system is also resistant to chemicals, moisture, and abrasion, making it a popular choice for industrial and manufacturing facilities.

This makes epoxy flake flooring is an excellent choice for anyone looking for a durable, low-maintenance, and visually appealing flooring option.

What Are The Benefits Of Epoxy Flake Flooring?

Epoxy flake flooring is an excellent flooring system that offers a wide range of benefits for both residential and commercial applications.

Here are some of the benefits of epoxy flake flooring:

Durability:

Epoxy flake flooring is known for its durability and longevity.

It is resistant to abrasion, impact, and chemicals, making it ideal for high-traffic areas like garages, workshops, and industrial spaces.

The epoxy coating protects the concrete slab from wear and tear, and can extend the life of the flooring for many years.

Slip-Resistance:

Epoxy flake flooring is slip-resistant, providing a safer environment for employees, customers, and residents.

The flake system creates a textured surface that increases traction and reduces the risk of slips and falls.

This is especially important in areas where spills or moisture are common, like kitchens, bathrooms, and entryways.

Low-Maintenance:

Epoxy flake flooring requires minimal maintenance and is easy to clean.

The surface is non-porous, so spills and stains can be easily wiped away with a mop or cloth.

The flooring is also resistant to mold and mildew, making it a great choice for humid environments.

Aesthetics:

Epoxy flake flooring is available in a wide range of colours and patterns, making it a versatile flooring system that can be customized to fit any décor.

The vinyl flakes can be mixed and matched to create unique designs, logos, or patterns.

This makes it an excellent choice for businesses or homeowners looking to create a customised space.

Cost-Effective:

Epoxy flake flooring is a cost-effective flooring system that offers a high return on investment.

The installation process is quick and easy, and the flooring can be installed over existing concrete, saving time and money on demolition and removal.

Additionally, the low-maintenance requirements and long lifespan of epoxy flake flooring can reduce long-term costs associated with flooring replacement and maintenance.

All of this makes epoxy flake flooring an excellent choice for anyone looking for a durable, slip-resistant, low-maintenance, and visually appealing flooring system. Whether you're a homeowner, business owner, or industrial facility manager, epoxy flake flooring offers a wide range of benefits that make it a smart choice for any application.

What Are The Latest Trends In Epoxy Flooring?

Epoxy flooring has been a popular choice for many years due to its durability, low-maintenance, and versatility.

In recent years, there have been several trends emerging in the world of epoxy flooring.

Here are some of the latest trends in epoxy flooring:

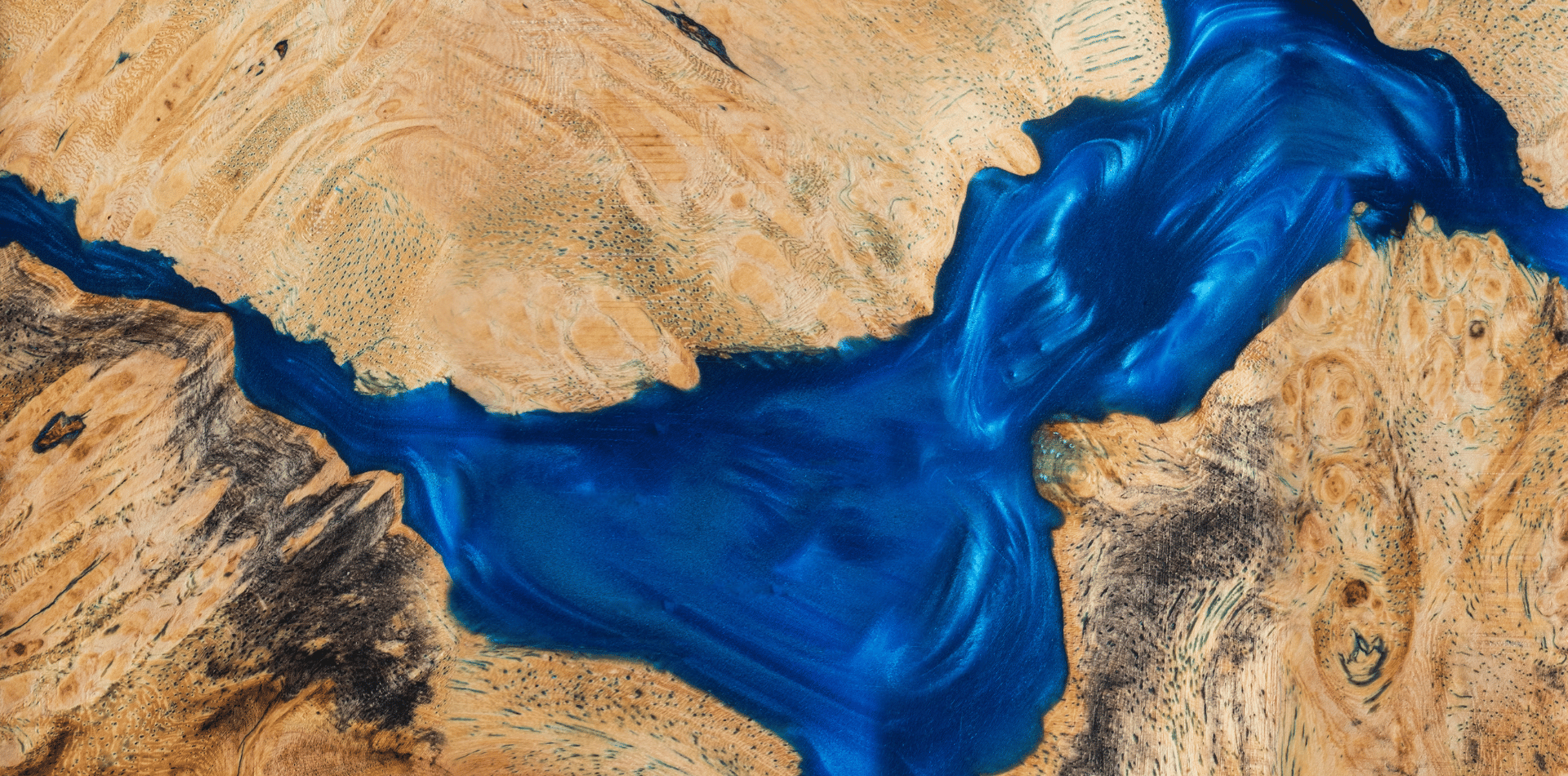

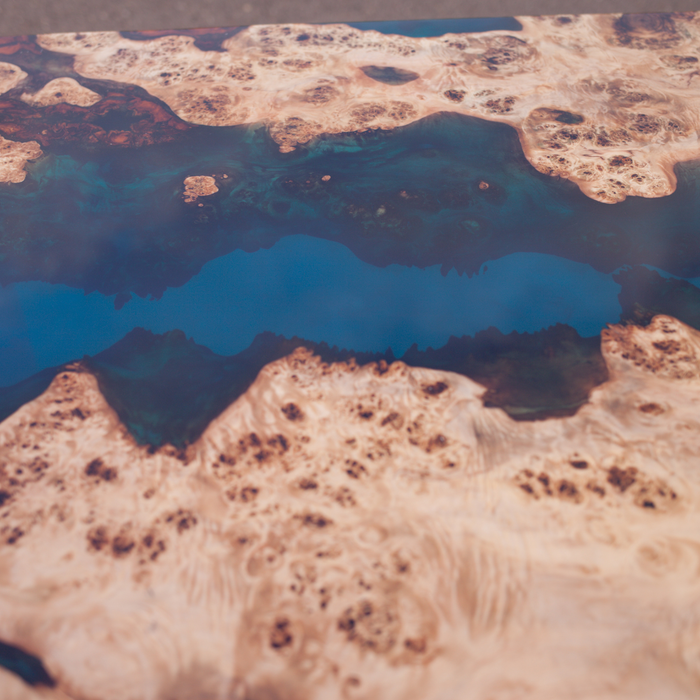

Metallic Epoxy Flooring:

Metallic epoxy flooring is a relatively new trend that has gained popularity in recent years. This type of flooring uses metallic pigments to create a unique, marbled effect that looks like polished concrete with a reflective finish. Metallic epoxy flooring is available in a range of colours and can be customized to create a one-of-a-kind look.

3D Epoxy Flooring:

3D epoxy flooring is another trend that is gaining popularity. This type of flooring uses a clear epoxy resin and a printed image or design to create a 3D effect on the floor.

The result is a stunning, eye-catching floor that can be used in commercial or residential settings.

Coloured Epoxy Flooring:

Coloured epoxy flooring is a trend that has been around for some time but continues to be popular. This type of flooring uses pigmented epoxy resin to create a uniform colour on the floor. Coloured epoxy flooring is available in a range of colours, and the pigments can be mixed to create custom colours.

Epoxy Flake Flooring:

Epoxy flake flooring is a classic epoxy flooring trend that continues to be popular. This type of flooring uses coloured vinyl flakes that are broadcast onto the wet epoxy resin layer to create a decorative finish. Epoxy flake flooring is available in a range of colours and can be customized to create unique designs.

Stained Concrete:

Stained concrete is a trend that has been around for many years but has recently gained popularity in the world of epoxy flooring. This type of flooring uses acid-based stains to create a marbled effect on the concrete floor. The result is a unique, natural-looking floor that can be customized to fit any décor.

The latest trends in epoxy flooring include metallic epoxy flooring, 3D epoxy flooring, coloured epoxy flooring, epoxy flake flooring, and stained concrete. These trends offer a range of options for homeowners, business owners, and industrial facility managers looking to create a unique, durable, and visually appealing flooring system.

Can I Epoxy a Floor myself?

Yes, it is possible to epoxy your floor yourself.

Epoxy flooring is a popular choice for both residential and commercial spaces because it is durable, long-lasting, and easy to maintain. However, it's important to note that applying epoxy to your floor can be a challenging and time-consuming process that requires careful preparation and attention to detail.

Here are some general steps to follow when applying epoxy to your floor:

Preparation: Thoroughly clean and dry the floor, removing any dirt, dust, or debris. Repair any cracks or imperfections in the surface.

Acid Etch: If you have a smooth or non-porous floor, you'll need to etch the surface using a solution of muriatic acid and water.

This process will help the epoxy adhere properly to the surface.

Apply primer: Apply a coat of primer to the floor and let it dry completely. This step is important to ensure the epoxy adheres properly to the surface.

Mix the epoxy: Follow the manufacturer's instructions carefully to mix the two-part epoxy together.

Apply the epoxy: Pour the mixed epoxy onto the floor in sections and spread it out using a roller or squeegee. Be sure to work quickly to avoid the epoxy drying before you can spread it out evenly.

Allow the epoxy to dry: Let the epoxy cure for the amount of time recommended by the manufacturer.

Keep in mind that these are general steps, and the specific process may vary depending on the type of epoxy and the condition of your floor.

It's important to carefully follow the manufacturer's instructions and take any necessary safety precautions when working with epoxy.

If you're unsure about your ability to complete the process yourself, it's always a good idea to consult with a professional.

A professional, like Kaptol Epoxy Flooring, can ensure that the job is done properly and can also offer advice on the best type of epoxy for your particular flooring needs.

Surface Preparation: The Foundation of a Successful Grind and Seal Flooring

Surface preparation is a crucial first step in the grind and seal flooring process.

The quality and durability of the finished floor depend significantly on how well the surface is prepared before grinding begins. Proper surface preparation ensures a smooth, uniform, and adherent base, which is essential for achieving the desired aesthetic and functional results.

Surface preparation is important to gain a good result, here's why each step is important.

1. Thorough Cleaning of the Concrete Surface

The preparation process begins with a comprehensive cleaning of the existing concrete surface. This involves removing all dirt, dust, grease, oil, adhesives, paint, and any other contaminants that could interfere with the grinding and sealing process. A clean surface is vital because any debris or residue can hinder the grinding machine’s ability to work effectively and prevent the sealant from properly adhering to the concrete.

- Methods of Cleaning:

- Sweeping and Vacuuming: The initial step usually involves sweeping the area to remove loose dirt and debris, followed by vacuuming to pick up finer particles.

- Pressure Washing: For stubborn dirt, grime, or stains, pressure washing is often used. This method involves using high-pressure water jets to clean the surface thoroughly.

- Chemical Cleaners: In some cases, chemical cleaners or degreasers may be necessary to remove oil stains, grease, or other contaminants. These substances break down the oils and residues, making it easier to wash them away.

Proper cleaning ensures that the grinding process is smooth and uninterrupted and that the sealant bonds correctly with the concrete, providing a durable and long-lasting finish.

2. Removal of Existing Coatings

If the concrete surface has existing coatings, such as paint, epoxy, or sealers, these must be removed before the grind and seal process can begin. Old coatings can prevent the grinding machine from reaching the concrete substrate evenly and may cause the new sealer to peel or flake over time.

- Methods for Coating Removal:

- Mechanical Grinding: The use of grinding machines with diamond-tipped blades or discs is one of the most effective methods to remove existing coatings. This process involves systematically grinding away the top layer, exposing the bare concrete beneath.

- Chemical Strippers: For some types of coatings, especially thick or stubborn ones, chemical strippers may be applied to dissolve and soften the material, making it easier to scrape off.

- Shot Blasting or Scarifying: These methods involve propelling small steel pellets (shot blasting) or using a rotary cutting tool (scarifying) to remove coatings and roughen the surface. They are effective for heavy-duty coatings but may be overkill for lighter coatings or delicate finishes.

Removing old coatings is essential to ensure that the new sealant adheres properly and the final finish is smooth, consistent, and durable.

3. Inspection and Repair of the Concrete Surface

Once the concrete is clean and free from coatings, the next step is to inspect the surface for any cracks, chips, spalls, or other imperfections that could affect the quality of the finished floor. Identifying and repairing these flaws is essential to creating a smooth and even surface for grinding and sealing.

- Common Surface Imperfections:

- Cracks: Cracks can develop due to natural settling, temperature fluctuations, or heavy loads. Left untreated, they can grow and cause the floor to deteriorate over time.

- Spalling or Flaking: Spalling occurs when pieces of the concrete surface break away, often due to freeze-thaw cycles, exposure to harsh chemicals, or improper curing.

- Pitting: Pitting refers to small, round depressions or holes in the surface, typically caused by wear, impact, or exposure to corrosive substances.

- Repair Methods:

- Crack Filling: Cracks are typically filled with an epoxy or polyurethane crack filler, which is injected or applied into the crack to seal it. This process prevents further expansion and ensures that the floor is smooth for grinding.

- Patching Spalls and Holes: Spalls, chips, and holes are patched with a concrete repair compound or a cementitious overlay. This material is applied to the damaged areas, leveled, and allowed to cure, resulting in a smooth, even surface.

- Smoothing Uneven Surfaces: In cases where the concrete surface is uneven, self-leveling compounds may be used to create a uniform base. These compounds are poured over the surface and spread evenly, filling in low spots and leveling out high areas.

4. Profiling the Concrete Surface

After cleaning, removing coatings, and repairing imperfections, the surface must be properly profiled. Profiling involves creating a textured surface that will allow the sealant to bond effectively to the concrete. This is typically done by grinding the concrete with coarse-grit diamond tooling to open up the pores of the concrete and create a suitable texture for adhesion.

- Importance of Proper Profiling:

- Profiling ensures that the sealant penetrates the surface adequately and bonds well with the concrete, which is essential for long-term durability and resistance to wear, stains, and moisture.

- It also helps achieve the desired aesthetic finish, as different levels of grinding (from light to heavy) will expose varying degrees of aggregate, allowing for customized appearances.

5. Moisture Testing

Before the sealing process begins, it’s essential to test the concrete for moisture. Excess moisture within the concrete can cause sealant adhesion problems, leading to blistering, peeling, or discoloration over time.

- Moisture Testing Methods:

- Plastic Sheet Test: A simple test involves taping a plastic sheet to the concrete floor for 24-72 hours. If condensation forms underneath, it indicates excessive moisture.

- Moisture Meters or Probes: These devices can measure the moisture content within the concrete more accurately, providing a clear indication of whether the surface is ready for sealing.

If moisture levels are too high, it may be necessary to delay sealing until the concrete has dried sufficiently, or apply a moisture barrier or vapor barrier coating to mitigate the issue.

6. Final Surface Cleaning

Before proceeding with the grinding, a final cleaning of the surface is done to remove any dust, debris, or loose particles generated during the previous steps. This step ensures a clean slate for the grinding process and optimal sealant adhesion.

Surface preparation is a meticulous and multi-step process that lays the foundation for a successful grind and seal flooring installation. Each step — from cleaning and coating removal to repairing imperfections, profiling, moisture testing, and final cleaning — is vital to achieving a durable, attractive, and long-lasting floor. Proper surface preparation not only enhances the aesthetic appeal of the finished floor but also ensures its performance and longevity, making it an essential part of the grind and seal flooring process.

Our Commitment to our Clients

The best and most productive relationships are synergistic and goal-oriented, and a long-term relationship has the value add of deep-rooted industry and company knowledge and relationships.

Proudly associated with Wood Floor Refinishing Virgnia Beach USA

Get a Free Quote

For a quote or any questions regarding Epoxy Flooring please fill in your details in the form below.

Contact Us

We will get back to you as soon as possible.

Please try again later.

Part of the

Kaptol Epoxy Flooring is the leader of epoxy floor installation and repair in the Newcastle, Lake Macquarie and Hunter Region.

Get Started Now

| Powered by Kaptol Media